… and his role in the early days of Mills Novelty Co.

© Rick Crandall, 2016

This is an important, previously untold story from the early days of the creation of the coin-op gaming and amusement machine industry. It presents, with a rare first-hand account, a whole new view of how the Mills Novelty Company got its legs to become the largest and most successful in its field. However it is also an account of a man who exemplifies the strength of character, inventiveness and individual entrepreneurialism that has been the backbone that built the United States from a melting pot of immigrants seeking the American dream – and achieving it.

This is a story that the late Dick Bueschel, the most recognized researcher and author of gaming machines, would have loved to tell in this degree of detail. In fact it is partially due to him that I can. As a tribute to Dick’s passion, enthusiasm and tireless efforts to bring information to light about all aspects of the automatic entertainment-machine history, I will channel Dick and write the next paragraph in his inimitable style:

“Random finds might seem pure luck – and in a way they are – but if you work to make your own luck you just might have the same experience, often when you least expect it. The determined are in for a lot of heartache and wasted time. But … if after hard work, they finally make an original find … It’s a thrill that’s hard to describe. The stories are banter for a collector gathering with the exceptional tales becoming the collectors’ story of a lifetime.”

Discovering the combination diary and autobiography of John Gabel, the source of the rest of this story, is exactly one of those finds – Rick Crandall

Here is a real excerpt from Dick’s writings: “One of the excitements of collecting gaming-machine paper is that you become the purveyor of rare knowledge, the keeper of a long-flickered flame, and the holder of history. For myself, I long ago realized that although I wanted to collect every slot machine ever made I could not do so by virtue of limited machine-discovery, money and space. Yet, within the confines of four 4-drawer, legal-size filing cabinets, by concentrating on their paper, I can own them all.”

“The slot-machine boom of the late 1890’s was a function of the growth and inventiveness that exploded with the rapid expansion of machinery for mass production, steel foundries, machine shops – all part of the advances in the Industrial Age. Where a few scattered slot-machine manufacturers had existed in the early 1890’s, by 1897 many of the big names were being founded.”

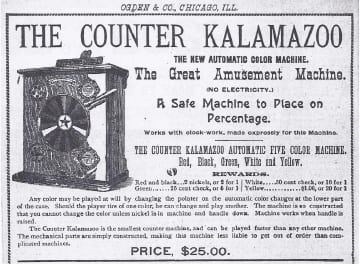

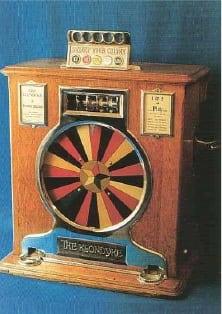

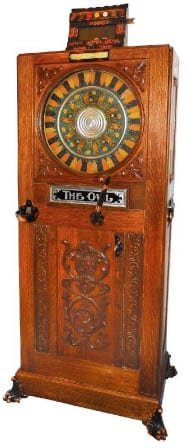

“When Herbert S. Mills first bought his father’s M.B.M. Cigar Vending Machine Company in the summer of 1897, [first producing] his early counter Kalamazoo, Klondyke and 5-way floor model The Owl. It was the Owl that made the whole idea of antique slot-machine collecting possible. It was the first successful all-mechanical floor machine with a color wheel payout, one of the first machines made by the newly formed Mills Novelty Company and the first slot machine to sell in the high 1000’s thus making it available in some numbers 75 years later. It was invented by Mortimer B. Mills, father of Herbert S. Mills, in 1897. Herb Mills, a barn burner, bought his father out and brought out the Owl early in 1898. It literally made him and the Company overnight. The Owl symbol also became the firm’s trademark.”

That last paragraph is how Dick described the Mills Owl – but by the end of this story we’re going to re-write and enrich the story – and a man by the name of John Gabel will take on a whole new light. You will learn from this account that without John Gabel, there might not have been a Mills Novelty Company!

John Gabel – Early Childhood – In His Words

“On the 24th day of May in the year 1872, I was born in Metzenseifen, Hungary. The mother tongue of the Metzenseifians is Low German. I remember well my family and the living conditions in my home when I was 3 years old. My father was a master nail smith and employed three fellowcrafts in his own shop. Every day I ran down to the shop with a potato in my hands. The boys would bake it for me over the fire. After eating the potato, I usually fell asleep on a pile of coal and, at quitting time one fellowcraft carried me home.

Metzenseifen’s first inhabitants were German. They were known for operating ironworks making blades, shovels and nails from iron. ore.

At the age of six, I started to school. My school days were limited to less than two years, scattered between the ages of six and ten. They were broken up by one sickness after another. At the age of ten, I was sent to work. I do not remember anything pleasant about my childhood days. At the age when most children have fun and excitement, I was down with some kind of disease. Scarlet fever was most unkind to me as it left me with a lot of sores on my head. These sores were not only painful but unpleasant to look upon. This condition prevailed until I was 13. At the age of 8, I suffered from a severe case of smallpox. My head was so badly swollen that I was blind for two weeks and unconscious most of the time. It was thought that I would die as other children of our town who had milder cases did not live. In those days, the doctors did not know much about contagious diseases. The doctor in our town was very old and I believe that he knew very little about medicine. He usually prescribed a home remedy for his patients.

At the age of nine I lost my mother. She and I contracted Typhoid fever on the same day. Mother died and I recovered. When I was 10 my father married again.

As a helper at age ten I worked in the shop with my father near our home. The work was hard and the hours were long. While working in the shop, I saw much misery among the apprentices. Along with their hard work, they were beaten by the masters. I saw them struck with a hot iron and their flesh burned and blood streaming down their faces. When they were unable to see, they were sent to the river to bathe their wounds and told to return to work.

About the end of 1883, my father moved his tools to a shop in lower Metzenseifen, about three miles from our home. Father and I worked together in this shop for about six months. Finally, he had to give up as master and take a job as helper. I was given to another master. My new master was a very fast worker. We started at 2 o’clock in the morning. At 7 o’clock, we stopped a half hour for breakfast and by noon we had to have one thousand nails finished so that the master could go home. In addition to helping to beat the nail out of the hot iron, the helper had to attend the fire, get the iron white hot and count every nail as it was made. Woe to the helper who made a mistake in his count.

At the age of 12, I worked as a blacksmith’s helper. Our home was 3 miles from the shop. At that time the blacksmiths in our town chose very peculiar hours. We worked from 2 o’clock in the morning until noon. The helpers stayed to pack the finished product, clean up the shop, rebuild the firepot and prepare enough charcoal and iron for the next morning. Then there was a 3-mile hike, not for exercise but to get home. I can remember many summer afternoons that I was too tired to go into the house when I reached home. I would lie down on the front lawn and sleep. When my father came home, he would pick me up and carry me into the house and put me to bed. He knew that I needed the sleep more than the dinner (such as it was) because I had to be up very early the next morning to return to work.

The master had all the power and he was the judge; the apprentice had no rights at all. In those days, the boys and girls of European countries had to enter into contract with a master of the trade which he chose to learn. The duration of the contract depended upon if the parents could afford to dress the boy during his apprenticeship, the contract was for three years. If the master had to clothe him, the boy had to work for four years to pay for the clothes and board such as the master supplied.

After a boy had labored for four years, he was still at his master’s mercy. His entire future working career was hinged on his master’s good will and temperament because he was the only man who could declare him a fellowcraft. The master presented him with a book into which he had entered the history of his behavior during the four years, after which it was stamped with the city seal. With this book in his possession, the newly-made fellowcraft started out into the world in search of work and success.”

Passage to America

“In 1885, my Cleveland, Ohio cousin, also named John Gabel, wrote to my father and asked permission to bring me to America if he would send the money for my passage. Although my father needed me to help support them, he consented and wrote John that I might go. One year later, my cousin sent the money and transportation to Cleveland for my sister Mary and me- it did not take long for us to get ready. I could wrap my extra clothes in a handkerchief. We packed our possessions in a bed sheet and left Metzenseifen the end of September, arriving in Cleveland on October 14, 1886.

An exciting experience in my life was my journey and arrival in this country. I was 14 and my sister Mary was 17. We traveled fourth class, just like the cattle in this country. The car of the European train in which we traveled was like an American freight car with the exception of windows and benches around the inside of the car. There were not enough seats for all of the passengers so we had to sit on the floor. At night the men, women and children were lying on top of one another, trying to sleep.

On the third day, we arrived in Bremen, Germany. We were unloaded there and placed in one room of a building at the harbor. We were told that each one would have to buy a pail to take his food on board the ship. Two persons were assigned to each bunk. My sister and I occupied the same bunk. The stench was awful. The place was crowded with people and there was no ventilation. I used my pail twice–for the first and last meals. Most of the others were seasick also. Those in the upper bunks vomited down on those in the lower bunks and nobody seemed to care. Those who were not too sick were crying and praying. The ship rolled so much that the people were thrown out of their bunks. Women and children were screaming. My sister was crying and praying at my side. One time she said, John, we are sinking. I said, let us sink. I don’t care. I was really too sick to care. On the tenth and last day we went on deck, glad that the end was so near.”

The Land of Opportunity

“When we entered the Baltimore Harbor and saw so many people on shore, I was quite excited. My one thought was to get away from the steamer and to leave that horrible experience behind. As we stopped at the pier, my excitement increased as I was so anxious to set my foot on the land of opportunity, to mingle with strange people and to start life anew. Among the people on the pier, I saw some well-dressed colored folk. It was the first time that I had ever seen a Negro and, in my excitement, I called to the others to look at the genuine Americans.

We were in quarantine for about 12 hours. Then they placed us on a train according to our identification cards. I was shocked to see so many upholstered seats in the day coach which we occupied. After the train was on its way, a boy came through the car selling fruit. We were hungry so my sister bought some bananas. We had never seen bananas before so we did not know how to eat them. We soon found out after I had bitten into the peel and thought the fruit was very good.

On the second day, we arrived in Cleveland. Cousin John Gabel was waiting for us at the station. He took us to his brother Paul who made us welcome in his home to live with his family. The next day, John took me to a clothing store and bought a complete outfit of clothes for me. The following Sunday afternoon, a number of friends and relatives came to the house to see the greenhorns. My sister Katherine, John Gabel and my stepbrother were among them. They looked us over and asked a lot of questions. I was dressed in a new suit; new shoes and a new hat for the first time in my life and John inquired how I felt. I told him that I felt swell only the shoes hurt a little. He said, ‘of course they hurt, you have them on wrong. Put the right shoe on the right foot and they will not hurt.’”

First Job in America

“After living with Paul’s family for four weeks his wife told me to go out and look for a job; that she did not intend to feed me for nothing. I was anxious to work but did not know where to go. The following morning I was on my way to look for work. At 7 pm I returned with a job.

It was hard for me to get work because I was weak and undernourished and weighed only 79 pounds. When I called at a place in search of work, they laughed at me and showed me the door. This also happened where I got the job but met the boss, Mr. Shapen, on the doorstep. On my way out I said Guten Morgen, Mein Herr.’ He looked at me and told me in German to come back. When he asked me what I wanted, I told him that I was looking for a job as blacksmith helper. He laughed and said, ‘my child, you ought to be in school, not work.’ I told him that I had come to this country to work, not to school; that I must find a job and earn my own living. He asked me how I knew that I could do blacksmithing. I told him that I had worked at it for four years and he laughed again.

I said to him, ‘I can see that you do not believe me. If you will look at my hands, you can see that I have worked with a hammer and out of the fire.’ He looked at my hands, then he grabbed them and said, ‘My God child, you really have worked hard.’ Mr. Shapen was the owner of Shapen’s Nut & Bolt Factory. He said to me: ‘I will give you a job but not as a blacksmith helper. We have light work that you can do.’

After three months I asked the superintendent to transfer me so that I could learn a trade. He put me in the brass department. The man in charge of that department was German, a good mechanic and well educated. Under him I learned a lot, not only in the mechanical line but in speaking English as well. After 4 months of the brass-finishing trade, I felt that I was efficient enough to try my luck elsewhere.”

Self-made, Self-educated

“At the age of 15, just nine months after I came to this country I realized that it was a great handicap to be without an education. I had to depend upon others who treated me as though I was a dumb kid. From this I learned a good lesson, that to be successful in this world, I must learn to do things myself and establish my independence.

My aim was to find a way to educate myself: First, to learn how to read and write in German, then to learn how to speak English and to read and write in English. I was 15 and lived with a German family in Cleveland. They read the German daily paper which gave me an opportunity to study reading. I knew the German alphabet and, by spelling the words, I got the meaning. Within two weeks I could read most of the words in the paper. Then I started to write the words and within two weeks I set up a letter and mailed it to my father. He was quite pleased with my efforts.

Independence means a lot in life but it is hard to protect. I had much to learn and many obstacles to overcome before I would achieve success. I found that this could not be done without the necessary qualifications, that a man must be ambitious, strong-minded, courageous and that he must have will-power and pride.”

John Gabel Goes to Chicago at 16

“Cleveland was not big enough to appeal to my friend John Waganer so he went back to Chicago. He wrote to me and he urged me to come to Chicago. He told me that there was a better opportunity there because Chicago was larger than Cleveland. His letters made me eager to start for Chicago.

In February 1889, at 16, I left my relations, friends and Cleveland and started for Chicago. I knew that my path of life was not covered with roses, that I was traveling on a hard, rocky road and that my only salvation was to prove to the world that will power, courage and ambition lead to success.

When I arrived in Chicago I could neither read nor write English. One day I stumbled upon an idea. With a newspaper in my hands I looked at the comics. Studying the pictures, I learned the meaning of them. Then I read the printing below the pictures. I found that this worked out all right and from that day on I studied the comic pictures every day. It helped me to learn how to read.”

Exposure to Communism in America

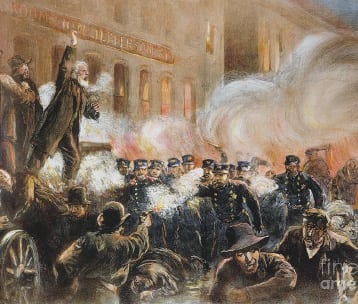

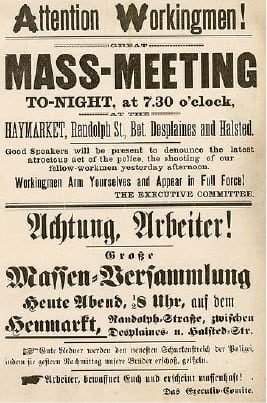

“I met some co-workers who would talk about freedom, that the working people must free themselves from the yoke of capitalism and oppression. One evening Frank Gedeon took me to a meeting. The attendance was very small that evening so he introduced me to everyone. After the preliminary business, the Chairman introduced Apple as speaker of the evening. Mr. Apple’s speech was somewhat radical. He called upon the working class to organize and free themselves from the yoke of the capitalist. He demanded freedom and condemned the government for the oppression of the masses. When he concluded, the audience applauded him with enthusiasm and cheered for anarchism. On the way home I asked Frank about the name of the organization. He said, ‘we call it the Communistic Union but all of those fellows you met this evening are anarchists. They meet as communists because the police have hated the anarchists since the Haymarket Riot.’”

“After the first meeting, I became a regular attendant. Finally, I joined the organization. Meanwhile, August of the A. H. Andrews Co. got me interested in the Metal Workers Union which I joined. I attended the meetings of both organizations regularly and the speeches made a regular proletarian of me. I did not know the meaning of the word but was quite proud of myself. Just as proud then as I am ashamed of it now. As time went on, I was recognized as a true member of the Communist Union. As a regular attendant of the meetings, I was appointed a delegate to the Communistic Council.

This 1886 engraving was the most widely reproduced image of the Haymarket Affair. No other single event has influenced the history of labor in Illinois or the United States.

The Haymarket riot refers to the aftermath of a bombing that took place at a labor demonstration on May 4, 1886, at Haymarket Square in Chicago. Someone threw a dynamite bomb at police as they acted to disperse the public meeting. The bomb blast and ensuing gunfire resulted in the deaths of seven policemen and at least four civilians. Eight anarchists were convicted of conspiracy. Four were hanged on November 11, 1887. The Haymarket affair is considered significant as the origin of international May Day observances for workers. The site was designated a Chicago Landmark in 1992, and a public sculpture was dedicated there in 2004.

It was my duty to attend every Council and Mass Meeting. I met the most radical and prominent members of the organization. Among others, I met Emma Goldman, Mrs. Spiece and Mr. Bergman. Bergman was one of the anarchists who was sent to the penitentiary after the Haymarket Riot. Mrs. Spiece was the wife of one of the three who was hanged. Emma Goldman, a radical anarchist, was later deported to Russia for making revolutionary speeches.

Mrs. Spiece was the chief speaker of the first mass meeting that I attended as a delegate. Before the meeting was opened, I sat and talked with her. The chairman introduced Mrs. Spiece as the speaker of the evening. As she stepped forward, she said: ‘Comrades, before I go on with my speech I wish to introduce the youngest delegate present.’ She asked me to step on the stage and then she introduced me to the audience. She said: ‘John, how old are you?’ I told her that I was 17 years old. Then she said: ‘It is surprising for one of his age to have knowledge of our principles and it is indeed encouraging.’ She said: ‘Comrades, in order to strengthen our organization and to hasten the revolution, we must educate the younger generation, to teach them our principles and make proletarians of them before they get too old.’

These speakers were so radical and unreasonable that an ordinary laborer (if he would use common sense) could see that their theory was impossible. In their speeches, they called upon the audience to organize and fight for freedom, to throw off the yoke of slavery and demand their rights, to abolish capitalism, to destroy its property and take possession of the industries. They told the audience that they were operating the industries for the bosses so why not operate for themselves. They told them that they were working ten hours a day to accumulate big profits for the bosses, that if all of the bosses and capitalists were put to work, it would require only two hours a day to produce what we were producing in ten. They shouted that we should demand two hours’ work for ten hours pay. They asked why we should work for someone who is not producing, that we are the cog wheel of industry and that if we quit everything would be at a standstill. At the conclusion of the speech, the audience would jump to their feet, clap their hands and cheer for anarchy. Of course, I did the same.”

Gabel Rejects Communism (A lesson to those advocating socialism today!)

“Of course these people did not have the faculties to think so they really did not know what they were talking about. If they had stopped to think, they would have realized that two hours’ work a day instead of ten with pay for ten hours is impossible. If the farmer would work only two hours a day, he would have to charge five times the price for wheat, the transportation would cost five times more, the hauling would cost five times more so that the flour would cost five times more. The baker would charge five times more for bread and the cost to handle the bread would be five times greater. In this way, the working man would pay for bread almost as much as he would earn in a week. Thus these agitators deceived the working people.

From contact with these people, I learned their method of living. Because their early life was a failure, they blamed the system and conditions that existed throughout the world. Their mouthpiece was their vocation. They made their living from these speeches and by creating disturbances among the working class. Some parts of their speeches were buried in my mind. I could never comprehend the demand for freedom. I believed that the working people of this country had all the freedom that they wanted. I did not think that it was fair to assail our government and to destroy the capitalist so I resigned the office of delegate. However, I continued to attend meetings regularly.

I became convinced that I was not the right timber to build up a strong Communistic Organization. So I quit the organization and everybody connected with it. I realized that I was traveling in the wrong path. My aim was to turn into the right path that leads to success and happiness. Thank God, I made the right turn at the right time.

I do not regret nor am I ashamed of what I have gone through. The experience has been an asset to me. I knew that the Anarchists, IWW’s, Communists and Nyalists (whatever they call themselves) are radicals and have the same doctrines. Their principle is terrorism, disorder and confusion. They teach the destruction of private property, the abolition of capitalism and revolt against the government. They disregard the law and condemn religion. They aim to control the laboring class with the unreasonable speeches and to keen them dissatisfied. If these agitators were abolished, the working class would keep at work peaceably and satisfied.

I remember the trouble in this country in 1917, during the World War. At that time, the agitators called themselves IWW’s (International Workmen of the World). They traveled in groups or three throughout the West and Northwest. They called strikes in the copper mines, lumber mills and among the fruit pickers and harvesters. Their speeches were repeated on the witness stand at the trial of the IWW’s in 1918 where I happened to be on the jury.

Their speeches reminded me of the past as they were identical. At Bizbee, Arizona, they told the miners that the country was at war and that thousands of working men were being killed with the copper that they were picking out of the earth; that the government was in need of more men and more copper to make ammunition and that this would be the time to strike and strike hard. They demanded 6 hours of work a day for 10 hours’ pay. Later they asked for 4 hours and then 2 hours’ work for 10 hours’ pay. Their story was that the government needs the copper too much to refuse. Then after the hours are granted, we will take the mines away from the capitalists and operate ourselves at our terms.

Thank God that our “G” men did not wait long enough for them to get six hours a day. They swooped down on the IWW’s all over the country at the same time and brought them to Chicago for trial. One hundred and fifty-three of them were convicted. After these agitators were abolished from the field of trouble, the workers returned to work in peace. I am glad that the description of my radical life is now ended so that I can continue in peace.”

Gabel’s Next Job – Learning the Engine Lathe … and then Complicated Mechanics

“In the summer of 1889 I went to work for Adams & Westlake Co.as a brass finisher. I liked the place and got along very well with the foreman. Adams & Westlake had a large factory and manufactured many different articles. This gave me an opportunity to acquire more knowledge.

After working for Adams & Westlake for about a year, I was taken from the brass department and sent down to the machine shop. This was a new job to me although I had worked on an engine lathe before. I was now in charge of an engine lathe and it made me very happy. I worked there for a year and then looked elsewhere again.

Engine Lathe. Originally developed to machine engine blocks; has power feed instead of foot-power

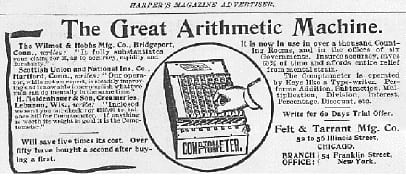

Still in search for learning, I next landed a job at Felt & Tarrant, assembling adding machines known as Comptometers. Mr. Felt was a very good mechanic and the inventor of these machines. He looked me over and inquired what I could do. I told him where I had been working and the kind of work I had been doing. He told me to come with him into the factory. I followed him to a speed lathe. He asked me what kind of a machine it was and if I knew its use. I told him that it was a speed lathe and I was familiar with its use… that most of the time it is used for turning. He picked up a hand tool, handed me a piece of wire rod and asked me if I could turn down a small shaft. I asked the size and he showed me a stick pin which he pulled out of his coat. I looked at the pin, then at him and told him if his work required so fine a shaft that I could do it but not on that lathe. I told him that I would use a screw machine for that work. He grinned and told me to come to work the next day.

1896 Comptometer Ad from Harper’s Magazine and an extant machine.

I knew the answers because I had been working on speed lathes for four years and had turned out many things from brass, iron and steel. The fine work was complicated and delicate but I was used to that. I was put to work assembling the Comptometer and within a couple of months I was doing so well with my work that the foreman tried me on the tool work. He then gave me some dies to make and that put me into another class. Tool and die makers are in a class of their own.

In spring of 1892, business in Chicago was bad and the adding machine business suffered. Felt & Tarrant had to lay off help and I was included.”

John Gabel Marries Josephine Berretta

“Saturday, September 17, 1892, was one of the great days of my life. Josephine Berretta and I were married. She was seventeen and I was twenty. We were very young and may have been foolish at the time but we have never regretted the step. With her support I tried my hand at a business in farm-supply with a financial partner. [This was a 3-year story of business mistakes and an inadequate partner. After recognizing the failure and still with Josephine’s staunch support …] I went in search of a job. For several days I walked many miles and finally landed a job on Clinton Street.”

Here is Where It Gets Really Interesting – At Age 24, John Gabel Meets Herbert Mills

“I went into the Link Belting Building on Clinton St. where there were a number of small machine shops. I visited each one. The last one was a new concern on the 2nd floor. It was not much of a place, just a small space divided into an office and work shop. At the window was a work bench with about four vises. In the center of the floor was an old engine lathe, a speed lathe and two drill presses. One of the men in the office saw me and asked what I was looking for. When I told him that I was out looking for a job, he said: ‘So you are looking for a job, eh? Are you a first class mechanic?’ I told him that I did not pretend to be a first class mechanic but a good machinist and assembler. He told me that he could use another first-class mechanic like the foreman and his brother, that both of them were first-class mechanics.

Then he said: ‘Just what can you do?’ I stretched my neck to look into the shop again and said: I don’t pretend to be a first-class mechanic but I can do all the work you have in this shop. He did not like that remark so he told me that I was getting fresh and to get out before he kicked me out. Before I reached the elevator, a man in the office called me back. He had heard the conversation. I stepped inside and he asked me two questions. ‘Where did you work before?’ I told him that I had worked for Felt & Tarrant assembling Comptographs and Comptometers. ‘How long did you work there?’ I told him that I had worked there three years. ‘Well all right. You may come to work at seven tomorrow morning.’

When I arrived at the shop, I reported to the foreman, he said: ‘You are an assembler, I assume you should have no trouble getting along.’ Before long, Elliott, the bookkeeper walked into the office.

He is the man who called me back the day before. When I said ‘Good Morning’ he looked at me and asked why I did not go to work. I told him that I did not know what to do. He said: ‘Oh shucks’ and spoke with the foreman for a few minutes, he returned to me and told me to wait for Mr. Mills. I was afraid that if I waited much longer, I would lose my job so I asked him to show me where I could find the stock and a finished machine so that I could build them. Mr. Elliott got a finished machine and showed me where I could find the stock. I started to work at once and finished the first machine [possibly the Counter Kalamazoo], then the second and was just starting on the third when Herbert Mills came over to me. He said: ‘Let’s see,’ and taking the file out of my hand, he said: ‘This is the way that I was taught in school to file.’ I said: ‘They just taught you how to handle a file. If I should file that way, it would take me half a day to file this frame and I would lose my job. When I was 12 years old, I was taught in a shop how to use a file and I have been using it that way ever since.’ He turned and walked away and, in a low voice, he said: ‘I guess you know what you are doing.’”

Gabel Shows His Stuff at Mills

“The third day after I finished the third machine, Mr. Elliott called me into the office. He said: ‘I just want to tell you that this is the best-working machine that has been turned out in this shop.’ When I heard these words, I really wanted to kiss him but merely thanked him and said that it does make a man feel pretty good to know that he is doing the right thing.

It is evident that Mr. Elliott passed on the word about the best-working machine. Two days later, Mr. Mills came to me and said: ‘Young man, you have done well so far; you have proved that you are a good mechanic. I have another machine on which I wish to try you–to see what you can do with it.’ Just about quitting time, he brought a small machine to me. He called it the Roulette and said: ‘although it is small, we can make a lot of money with it if we can make it work. It is late now so I shall tell you about it in the morning. Then I’ll show you how it is made.’

The next morning, I went to see Mr. Elliott who told me that Mr. Mills would be here early this morning to show me about that small machine. He said: ‘You had better wait until he comes.’ II told him that I disliked hanging around doing nothing. I asked him if he knew where to find the parts for that machine. Elliott finally agreed to show me where to find the stock and I started to work on the Roulette machine I did not know how the old machine was constructed as it was locked and I could not see the interior.

Gabel/Mills Little Monte Carlo “roulette”

Mr. Mills did not show up until 11 o’clock, just after I had completed the first machine. He came to me and said: ‘I am sorry to be so late as I wanted to show you the trouble that we have had with this machine.’ He stopped, and asked where this machine came from. I told him that I built it while waiting for him. He placed a slug in the slot and worked it. Then he said: ‘Gee, this works easy. Gosh, notice how smooth and quiet it is.’ He turned around and called Billy to come over. Billy was Mr. Elliott. When Billy worked it, he said: ‘It works fine but will it stand up?’ I said: ‘What do you mean?’ He said: ‘Those that we have sent out are coming back and falling apart like this one,’ pointing to the old machine that Mills brought in the day before. I told him that the machine I built would not fall apart.

Mills was very anxious to see the difference in the two machines. I asked him to unlock the old one so that I could take both machines apart and compare the workmanship. I took the mechanism out of the cabinet and saw that the mechanism was partly in pieces. Mills pointed at it and said: ‘That is what I mean.’ I said: ‘Let us take one thing at a time. First, that spring is too powerful for this mechanism.’ Mills said: ‘That heavy spring is necessary to spin the table.’ Then I pointed to the end of the shaft that it was just as if it was cut off by the shears and the end grinds and cuts at the bottom of the hole. He said: ‘that is not our trouble’ and again he pointed to the cylinder that was partly in pieces. I said: ‘I know, but this shaft is part of your trouble.’ Then I removed the table from the machine that I built and showed him that the point turned down at the end of the shaft is acting like a ball bearing and that is why a very light spring would revolve the turntable.

Mills said: ‘I see. It works like a ball bearing.’ I picked up the cylinder which was partly in pieces and said: ‘This cylinder is made of four pieces that are held together by two ends. On this end of the cylinder is a 4-point cam which is fastened to the same shaft as the cylinder. This cam must raise the arm with that heavy spring on it and as soon as the arm goes over the point of the cam it comes down with a bang which jars the cylinder into pieces.’

When both men said that my explanation was clear to them, I proceeded to show them the difference in the construction of the two cylinders. I reminded them of the coin slot between each two sections and that if the cylinders are not properly tightened they would become loose and the slots would be out of line. Then I showed them that the old cylinder had fallen apart because each section of the cylinder was held together by only one screw and the jar of that heavy spring loosened the screws and caused the cylinder to fall apart. I showed them where my cylinder had a pin in addition to the screw and that the pin would hold the cylinder tight so that the screws would not come loose. This explanation was quite lengthy but my future depended upon it. After I had reassembled the little Roulette machine which I had built, Mills took it under his arm and walked out.”

The “Gabel’s” Monte Carlo Goes Commercial

“The next morning when Mills carne in, he walked directly to me and said: ‘Gabel, the little Roulette is working fine. Now we must get busy and build them fast. If any of your mechanic friends are out of work, bring them in and put them to work. Put on two or three right away.’ Well I was doing pretty good. Within a week I was put in charge of the Roulette department.

Gabel Re-designs Every Mills Machine!

When I had been working for Mills three weeks, he came to me one day and said: ‘Gabel, here is our new machine. The foreman has been working on this machine for over four months. It has cost me several thousand dollars and when we put out the first few machines they did not work. Instead of making money for me, I had to pay the location owner from my own pocket because the public had been cheating. If the handle is pulled down fast, the dial will not spin so they worked the machine to get the dial on the dollar mark and then pumped out the nickels.’

I told him that I would fix it so that the dial would always spin when a nickel is played in the machine. He asked me if I could fix it by evening and I told him that it would be done in two hours. My assurance pleased him and he walked away. I took the machine out of the cabinet, then set the throw arm out of center and put a stop pin above the pawl so that it would not throw up too high above the ratchet. With this correction, it was impossible for it to fail.

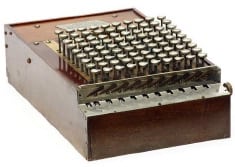

Kalamazoo advertised in 1897 Ogden catalog

This was likely the Kalamazoo, a next step up in mechanism with a 5-way coin head and $1 payout.

The next day, Mills came in with another new machine known as the Klondyke. His father was with him. Both came to my bench with the machine. Placing it on the bench, he said: ‘Gabel, these machines do not stand up.’ I said: ‘The machine that I fixed yesterday will never fail to spin the dial.’ He said: ‘The part that you fixed works fine and that is why I came to you with this one. I want you to fix them so that they will stand up and work 24 hours a day instead of breaking down every hour.’

I said: ‘Let me take out the mechanism so that we can look at its construction’. The old man who was a cripple and walked with a cane spoke up and said: ‘That is just what we want you to do so that you can tell us what can be done about it.’ Herbert then told me that the old man was his father.

When I had inspected the mechanism, I told them that the idea was all right but that the construction was faulty. Herbert said: ‘Well, I want you to fix it.’ I told him that I could fix it but that it would be just as bad the next day. The old man asked what I would suggest.

Mills/Gabel’s Klondyke

He told me to speak up, that he was an inventor and had been experimenting all his life so he knew something about mechanisms. ‘I said: If you want a good machine, it must have a good foundation.’ Herbert said: ‘What in hell has a foundation to do with this machine?’ I said, ‘this mechanism is built on a wood board and a board will shrink, warp and expand.’ Pointing to a crack, I told him that it was the cause of his trouble, that the crack made the levers too short. The old man looked at it and said: ‘Herbert, he is right.’ I continued: ‘This mechanism is built in six sections whereas it should be in one section only.’

Herbert started to swear and when I had heard enough, I suggested that we get busy and do something. Then he asked what I intended to do. I said:’ I would make a frame pattern which would do away with these six sections as well as the board. As soon as we get a casting, I would make a jig to drill all of the holes.’ He said: ‘For God’s sake, that will take time and lots of money.’ When I told him that it would take about three weeks, he started to curse again (the Mills family did that very well). The old man said: ‘Herbert, he is right. That is the only thing to do. Let him start immediately.’ Herbert told me to go ahead and to lose no time. Then they walked away.

The Gabel’s Klondyke Is a Success – and Gabel Becomes Foreman of Mills Novelty Company

I got busy and ordered the brass that was needed and started to work on the patterns. When the frame pattern was finished, Herbert looked at it and said: ‘Now we have something. I could kick that dirty son of a ??? in the corner. I will kick him out.’ So he went to the foreman and his brother and told them to pack their tools and get out. Then he turned to me and said: ‘Gabel, you go to the corner and take charge. From now on, you are boss of this shop.’

Three weeks before this incident, the same man had refused to hire me because I did not claim to be a first-class mechanic and now his first-class mechanics were leaving while he was smashing up the 12 Klondykes which had been built. Within three weeks I had been promoted twice. First, to take charge of the Roulette machine. Second to become foreman of the shop.

The Klondyke was in production very soon. The name was taken from a gold mine in Nevada. It brought us a lot of business. The Klondyke was a 5-slot gambling machine. Its dial was divided into 50 spaces. Two blues were supposed to pay $1.00 each; four greens $.50 each; eight yellows $.25 each; eighteen reds and eighteen blacks $.10 each.”

Gabel Encounters the Ethics of Gambling Machines

The orders came in so fast that I had to run the shop overtime. I noticed that one or two fellows would come in every day to have one or two plugs put on the pay-off ratchet. One day when Herbert came to me with a machine, I asked him why these plugs on the ratchet were wanted. He told me that it was to prevent the machine from paying off so much. I said: Do you think that it is fair? I call that cheating. He said: ‘You had better not talk that way before an operator or he will knock your block off. The public want to be cheated.’ Then I said that I do not want to be cheated, he asked me if I had ever played one of these machines on the outside? When I told him that I had not, he said that I had no kick coming.

After he left me, I thought about his remark that the public want to be cheated and that if the machine did not pay well, we would not get any business from the operators, and that if we did not get the business, I would lose my job which was a very important thing to me. So I decided that it was up to me to put the plugs on the ratchet.

I thought that I would fix the ratchet with six adjustable plugs; I made one up the next day and showed it to Mills. When he saw it he jumped in the air and yelled to Bill to look at the Automatic Plugging System that Gabel had made. Putting it in his pocket, he went out to show it to an operator. The next day he brought it back to me and said that it was the best thing that we had made yet. He told me to go ahead and fix the pattern for it. He placed the ratchet on the bench and walked away.”

Catastrophe Hits the Mills Factory

“Unfortunately the Link Belt Building was burned down that very day. When the alarm was given, Mills came rushing into the shop and ordered everybody to hurry out. My tools were scattered here and there so I had to rush all over the shop to pick them up. By that time, everybody was out and Mills came in again to yell: ‘Gabel, you damn fool, can’t you see that the shop is full of smoke and that the fire is spreading?’ I said: ‘Just a second, I want to grab my tool chest.’ Glancing at the bench, he saw the ratchet with the plugs on it. He grabbed it and said: ‘The damn fool is so careful to get his tools that he leaves the new invention, which is worth $50,000, to be burned up.’ I told him that the ratchet is not worth anything to me, that I could make a new one if it is burned up but that I would have to buy new tools which would take money that I did not have to replace them.”

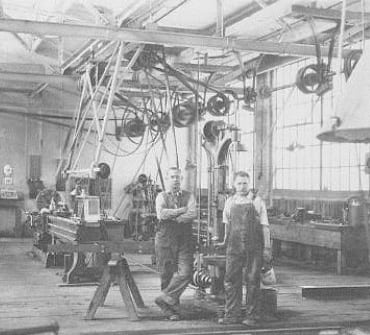

It Was Gabel Who Designed and Outfitted the New Mills Factory!

“Two days after the fire, I went into the wreckage to locate our stock. I picked up a frame and brought it out. I told Mills that I had located our stock and that we could get a lot out of it. He said, ‘Tomorrow I intend to sign the lease for a new location on the northwest corner of Randolph and Desplaines Streets. Meet me there at noon so that we can buy some new machinery.’ The next day we went shopping. At every machine house, he introduced me as his superintendent and told the salesmen to give Gabel anything that he wanted. I was very cautious as it was not an easy job to buy machinery including a 10-horsepower electric motor, main shaft, hangers and pulleys. I had to be very careful to get the proper speed on the main shaft and other machinery.

I decided to buy the electric motor first. I told the salesman to send a pulley for the main shaft with the electric motor large enough to reduce the speed of the main shaft line to 180 revolutions per minute. That would give me the base on which to figure the speed of the machinery. I made a list of the machines that were needed and submitted it to Mills for approval. He said that he did not know what kind of machines and how many were needed, that is why he brought me along and told me to figure on doubling our capacity.

The next day delivery of the machines started. With a couple of fellows to help, we put up the hangers for the line shaft. In a week we were in production and I started to put on more men including some of my old friends such as Harry Brown as pattern maker, Jack Ross as inspector and Joe Schmidl. Everything was running smoothly.

Typical factory of the type Gabel is describing.

One thing that I did not like was the fact that old man Mills was given a separate room in which to do his experimental work. Herbert told me that he put him there so that he would not bother the folks in the shop. Well, the old man stayed in his room for a time, and then he began to ask me to do little jobs for him. I did not mind it and was glad to accommodate him but he soon began to go to the men to have his work done and that slowed up production.”

The Owl – the First Upright – Conceived … and Made to Work by John Gabel

“I was never in his room so that I did not know what he was working on but finally I discovered that he was making a floor machine out of the Klondyke. He had been using ideas that he gathered from me to make the changes and he received the credit.

The 5-cent floor machine I was working on was nearing completion. I had Brown and a pattern maker working overtime on it so that we could start production on the machine that was called the Owl. Herbert Mills was eager to get it into operation. One day, as I passed Brown’s bench, I noticed that he was not working on my patterns. When I asked what he was doing, he said: ‘The old nuisance was here again and wants me to make this for him.’ I said: ‘Brown, you know that we need those patterns so you had better lay that aside and work on the patterns.’

In the afternoon, the old man came to my desk from the direction of Brown’s bench. He was very, very angry. Shaking his finger at me, he said: ‘You will regret this act against me for the rest of your life. Remember that I am the father of Herbert Mills and that I have a lot or influence over him. I warn you to watch your step.’ Well, he had spoken and the curse was upon me.

| The Owl – Mills’ first Upright |

The Owl was now in production but we had trouble with the coin slot. It was the old man’s idea. He built it. Herbert asked me to inspect it and give my opinion. I told him that it was too complicated and that a quick jar would put it out of order. The old man said that Gabel was a fool. When the trouble calls came in every day, the old man told Herbert that Gabel did not have a good assembler on the coin slots. So I was blamed for everything.

The old man persuaded Herbert to let Brown work in his room with him. The old man knew that Brown was my friend and believed that he could win him over to his side if he had him with him every day. That was an easy matter as I found out later.

Every day Brown would come to me and pretend to be my friend. We talked about the trouble that the coin slot was causing and he asked if I had thought of something to take its place. I said: ‘Brown, you know what the old man said when I criticized his slot. He called me a fool and said that I did not know what I was talking about. Under these circumstances, it would not be advisable for me to tell Herbert Mills that I could make a better slot for him than the one his father made. Ever since the old man got sore at me, I have been in hot water. Herbert has not asked me if I can make a better one.’ Brown asked me if I had an idea and I told him that I did.

From that day on, Brown asked me questions about my idea. One day I showed him the idea which I had worked out in a cardboard model. He said: ‘That is very simple.’ I said: ‘Yes, and it is fool proof.’ I kept this cardboard model in the bottom of my tool chest, covered by two shelves. So I did not discover that my model had been taken until they had made up a brass model and Herbert Mills, with a smile, asked me to inspect it. I couldn’t do anything about it. I had not shown the model to anyone other than Brown.

Then I went to Brown and said: ‘My cardboard model has been stolen from my tool chest. You were the only one who knew about it. Mills just showed me a reproduction of it and you made that out of the cardboard model which was stolen from my tool chest.’ He said: ‘What about it. You did not want to make it so forget it.’ Well, I never forgot it. Mills obtained a patent on it to prevent the other manufacturers from using it. My good friend Brown received the glory and the laugh was on me.

Mills Novelty Prospers … Gabel Quits …

The close of 1897 was outstanding in my life. I had worked very hard and others received the reward of my labor. Less than a year before, Mills was only a little gambler and now he was the head of Mills Novelty Co. employing 65 men. My brain and my efforts had made him. Mills Novelty Company made plenty of money but Herbert Mills was so high-hatted that I seemed like a pebble to him. He would not even recognize me. About two or three weeks before Christmas, Mills sent a man to California to open an office there end to operate slot machines. Within three months this man sent $50,000 to Herbert Mills as his share of the operation. Herbert Mills made his money fast. He had the three checks framed and hung them in his office. The revenue from his Chicago operation was very large. Herbert was growing while I was sinking lower and lower, beyond recognition. My friend Brown received the glory.

Mills called me into the office and said: ‘Gabel, I have made a change. I want you to go to work tomorrow in the experimental room. I have reduced your pay to $3.00 but if you make good in there, I will increase it.’ I said: ‘The change suits me but I will not work with your father. I am quitting.’ That ended my career with Mills. The Mills family came from very low-grade stock. Many times I heard Herbert call his father a bastard, an old fool and a crook. I have seen his brother Cecil go through the shop, pick up drills from the benches and when he had a tobacco can filled with them, he would sell it to the boys for $.50. When I left Cecil was appointed superintendent of Mills Novelty Company.”

… to Form His Own Company, The Automatic Machine & Tool Company

“In August l898 I was again out of a job. This time I did not go out to look for work. It came to me

instead. A few days after I quit Mills, I received several proposals.

The one I went with was Edward Mikkelsen who came to the factory to see me. He said; ‘Gabel, if you would go into the manufacturing business, you could make a lot of money for yourself. I know that you have the ability.’ I laughed and said: It takes more than ability to run a business and I do not have the means. He said: ‘It will not take much to get you started. I am willing to go into partnership with you.’ I said: ‘That would be fine. If you will agree to furnish the money, I will furnish the ability.’ He agreed.

I had known Mikkelsen for two years. He manufactured cabinets and he would supply the cabinets for the machines we would build and be in for the profit at both ends if we would make a go of it.

On Friday, October 13, 1898, I met Edward Mikkelsen at his office on North Jefferson Street between Randolph and Lake. Mr. Nielson wrote the agreement and, as he presented the two copies he called Mikkelsen’s attention to the day and date. Somewhat superstitious, Edward Mikkelsen told him to change the date to October 14. The written agreement was not like the verbal proposition made by Edward Mikkelsen when he said that we would be partners and share alike. The written agreement specified that Mikkelsen would receive two-thirds and that I would receive one-third. However, it appealed to me because the firm would be incorporated with a capital stock of $3,000. The name would be The Automatic Machine &Tool Co., and I would receive a stock certificate for $1,000 as my share of the corporation with a salary of $12.00 a week until the company would be on a paying basis at which time my salary would be increased.

The next day I went to Mikkelsen’s office to get things started. He told me to be careful about spending too much money for machinery. I said that it was my intention to buy second-hand machinery. I read the list to him – engine lathe, speed lathe, large drill press, small drill press and the vises. The planks for the benches would be supplied by Mikkelsen. I bought everything that was needed at a second-hand store on Canal and Van Buren streets. I set up the machinery and benches the following week and we were ready for work. First I laid out the dimensions on a board, and then I made some wood patterns for castings so that I could start my new machine. After that I was ready to hire some new help.

The first man I hired was Emil Mueller as pattern maker. As fast as I completed the experimental work, Mueller started on patterns. Instead of sleeping at night, I figured out my work for the next morning. As soon I finished with the experimental work, I started to work on patterns. Our working hours were 7:00 A.M. until 5.30 PM but sometimes I worked until midnight. By the middle of December, the iron castings started to come through from the foundry so I hired a boy to assemble. Before Christmas I had three machines finished and delivered them to Mikkelsen ready for the market.

Gabel the Mechanic – Who Also Had a Marketing Instinct

Mikkelsen said: ‘That is fine. Now if you have a good machine it will sell.’ I said: ‘Yes, I know that but we must spend some money to advertise.’ He said: ‘No John, I did not agree to put up money for advertising.’ I said: ‘We must advertise. How will a man in New York find out that we have a good machine?’ He said: ‘If you have a good machine, it will advertise itself.’ I thought that Edward Mikkelsen appreciated my hard work but his refusal to spend money for advertising caused me to change my opinion of him. When Mikkelsen and I started the business, I promised him that I would have a new machine completed in 3 months and by working my head off I had accomplished it in two months. By doing this I was saving him more money than the cost of advertising so I felt that Mikkelsen did not care to improve the business.

Why should I work day and night and get no results? I decided to start to work with the men in the morning and quit with them in the evening. Mikkelsen noticed this and one day he inquired why the machines were not coming along faster. I told him that the boys were working as hard as ever but he did not tell me that I was not working as hard as before.

I knew some operators in the city and I induced them to put a couple of our machines in operation for a trial. They seemed to like the machine and came back for more but this was a slow method of increasing business. Mikkelsen soon tired of it and I believe that his secretary, Mr. Nielsen, persuaded him to get out. Mr. Nielsen was quite a character. He went over Niagara Falls in a barrel and shot the rapids in a special boat, nearly drowning in the giant whirlpool. Then he crossed Lake Michigan in a contraption that was never attempted before nor since. He sat in the middle of a large wheel and worked it with his feet. He crossed the lake all right but when they pulled him out, he was more dead than alive. That was his last experiment. He tried to make a name for himself but the newspapers published that he was attempting suicide. When he read these reports, it was too much for him and he killed himself.”

Gabel’s Opportunity to Finally Control His Own Destiny

“In February 1899, Edward Mikkelsen offered to turn over his stock to me for $1500 and to cancel the bills for the cabinets that had been delivered to the company. I told him that it was a bargain but that I did not know where to get $1500. He said: ‘That is my offer to you so try to raise the money. This business really should be yours–just let me make your cabinets.’ I said that I would try. The next morning I called my men together. There were four of them: Mueller, Nelson, Overschlager and a very young man whose name I cannot remember but we can call him Patterson. I told the boys that I had a proposition and that it was too good to drop without giving it a chance that we might be able to figure it out some way. I told them of the Mikkelsen offer and that the question was how to raise that much money. Young Pattersen was the first to speak. He said: ‘Boy that is a good opportunity. This is a good paying business if it is operated right but Edward Mikkelsen is holding it back.’ I said: I know that there is a good profit in this business if it is managed right. If we could raise the money, I know of a way to make it pay.

First of all, I went to know if you fellows are with me and if so now much money can you raise. All of the boys said that they were with me. Then I said: ‘Let us see how much we can raise.’

I went to Mikkelsen’ s office and told him that I had $1300 to give him the following day that I had raised from employees and me, but that it would be necessary for him to wait for the balance of $200. He told me that the deal called for $1500 and that if I did not nave the amount, the deal was off. Then I said: You will not call off this deal for $200. You have always trusted me so why do you refuse to trust me now? You know that I will pay you. Looking at me, he said: ‘John, I know that you are honest but you told me that we must spend some money for advertising to make it pay. How can you make it pay if you do not have the money to advertise?’ I said: ‘That is true but I have some boys in the company who can operate the machines that we do not sell.’ He remarked: ’Oh! All right: Give me $1300 and I will sign over the stock to you. You may owe me $200.’ I said: ‘I knew that you would trust me, Mr. Mikkelsen.’”

John Gabel Owns His Own Company at 43 South Canal St., Chicago

“That meeting was in February 1899. At the meeting of stockholders, we elected three Directors. Then the Directors elected three Officers as follows: John Gabel, President, Emil Mueller, Secretary, Mr. Nelsen, Treasurer. In my short address to the boys, I told them that we had a hard road ahead of us but that we would not fail. Our first move would be to find a better location for our factory. I reminded them that we were occupying a cabinet shop and that slot machine operators would not care.to come there looking for machines. Then I told them that I would be very busy for a couple of weeks, looking for a location and contacting operators.

Within two weeks I found a suitable location in Canal Street. I also met a couple of the operators who promised to try our machines. Two weeks after our new organization started to operate, we moved to our new location at 43 South Canal Street. Although the floor space was in the rear of the building, it was facing an alley and court so there was plenty or light and air. During those two weeks business picked up to such an extent that it was necessary to employ more help in the shop as well as a bookkeeper.

I worked every night so as to fill the orders. So many orders were sent to Mikkelsen for cabinets that he called to find out if we were really shipping so many machines. Although I was working very hard, I was happy. I had no education in a business way but I was a born mechanic and was happy working day and night in the factory.

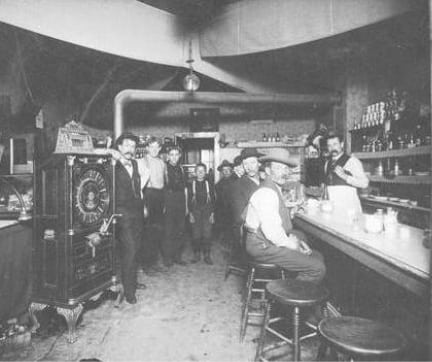

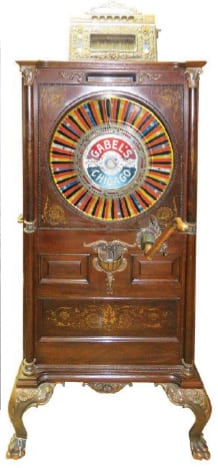

Gabel’s upright floor gambling machine, probably the Chicago model, inside the Stanton Restaurant;

Gabel’s Chicago, Rick Crandall collection.

I decided to advertise for a bookkeeper and stenographer. I hired a young lady, Miss Rose Carey. She was lame but a good worker and honest. With a stenographer in our employ, it was necessary to buy a typewriter which I purchased from a second-hand dealer for $15.00. Then I had to start to dictate letters. My dictation was about as good as my letter-writing. Miss Carey noticed this at once but she was not the kind that would joke and laugh at my mistakes. She just let me down gently.

She said: ‘Mr. Gabel, I know that you are very busy in the factory and your mind is on production. If you will just give me an idea of what you wish to write to your customers, I can write the letters. Then when you read them, you can tell me if there is anything wrong and I will write them over. After a couple of weeks I shall be able to take care of the correspondence.’ Miss Carey turned out to be a very trustworthy assistant to me.” [Years later, Rose Carey helped Gabel assemble and write this autobiography]

1899 and a New Life – The American Dream

“The business continued to grow and by the following spring it was necessary to acquire more space in the building. Fortunately, the front part of the floor was vacant so I took the entire floor of the front of the building. I moved the office to the front part so that the door was directly in front of the elevator. The company’s name was painted on the glass and it was very prominent. The year 1899 was an outstanding one in my life. The move from Jefferson Street to Canal Street brought my firm to the front.

Gabel’s Upright Machines, left to right: Owl (Jasper SanFilippo collection); Fox with Swiss music box, and a Niagara, case only (both from the Larry Debaugh collection)

My new life and real start in business began in 1899. Many things happened that year which I shall always remember. During the summer I took my first business trip to New York. I stopped at the Hoffman House where there was a $20,000 painting displayed in the lobby. This as well as the city itself and the stop over at Niagara Falls were real thrills to me. Late in the summer I took a trip to Cleveland to visit relatives and my first landing place in the U.S. That trip gave me satisfaction long to be remembered.

Inspiration Strikes Again

There is more to this story as Gabel went on to invent the first coin-operated multiple-disc phonograph commercialized in 1905 called the Gabel’s Automatic Entertainer. The Entertainer was all mechanical, playing acoustic records and amazingly changes the steel needle after every play.

In an article I wrote years ago focused on Gabel’s music machines, I hinted that this article on gambling machines would eventually be published. That article described the trigger for his inspiration for the Entertainer:

“But we’ll skip over that story (gambling machines) for now. We haven’t gotten to the music yet. In 1903, Gabel followed the lead of some other slot-machine producers who sought to establish the legitimacy of the gambling machines through the incorporation of Swiss music boxes that played whenever a nickel was deposited for a chance at a payout. The claim was that the nickel played was to hear the music rather than a gamble at a return (wink wink).

During Christmas of 1903, Gabel went to see Mr. Vosey from the Lyon & Healy Department Store, who was in charge of the Swiss music boxes. After concluding the sale of some music-box mechanisms to Gabel, Vosey drew attention to the talking machines. Gabel was biased against their noisiness and lack of musical quality – undoubtedly a correct judgment of the Victor and others with front-mounted horns and rigid tone arms. Gabel took a Victor home and surprised himself by liking the music so much that he played the records every night for some time.

He recalls: “While I listened to the music, I thought of the possibilities of this new talking machine for public use. At that time there was only one automatic nickel-in-the-slot instrument on the market that made money. It was very crude and the music was awful. It had a wooden roll with iron pegs driven into it. While the roll was rotating, the pegs would operate the piano keys to produce music. The entire system was copied from the Swiss music box”

We know that the machine he was referring to was the Wurlitzer Tonophone, indeed a crude affair, but it was the first on the market and Wurlitzer did well with it.

Gabel: “It occurred to me that an automatic talking machine would give better music to the public as well as a variety of selections both instrumental and vocal. I made sketches of an instrument of this kind and could not dismiss it from my mind.”

Gabel’s Automatic Entertainer 1905, first model.

Rick Crandall collection

What followed was his creation of the Automatic Entertainer, which, typical of Gabel’s mechanisms, was very reliable. But even more impressive is that his Entertainer was acknowledged by critical reviews to produce the highest-quality sound of any phonograph of its era, which precipitated a major fight by the Victor Talking Machine company that Victor eventually lost.

That entire story has been published by me in several journals and can be found at https://www.rickcrandall.net/diary-disclosures-of-john-gabel-a-pioneed-in-automatic-music/

Mechanism Photos of Gabel’s Chicago Upright Slot Machine: front, back, left side, right side. This is very different than the mech from any other manufacturer. Rick Crandall collection.

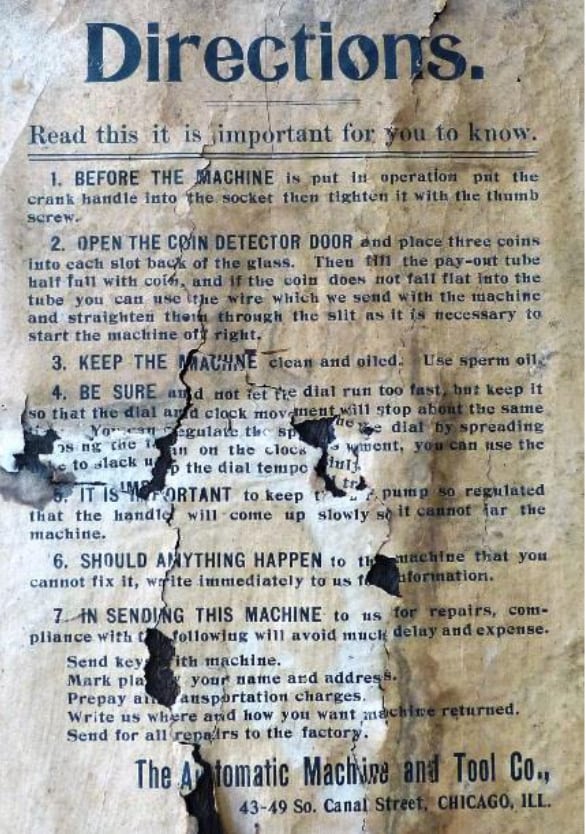

DIRECTIONS

- BEFORE THE MACHINE is put in operation put the crank handle into the socket then tighten it with the thumb screw.

- OPEN THE COIN DETECTOR DOOR and place three coins into each slot back of the glass. Then fill the pay-out tube half full with coin and if the coin does not fall flat into the tube you can use the wire which we send with the machine and straighten them through the slit as it is necessary to start the machine off right.

- KEEP THE MACHINE clean and oiled. Use sperm oil.

- BE SURE and not let the dial run too fast, but keep it so that the dial and clock movement will stop about the same time. You can regulate the spin of the dial by spreading xxosing the fan on the clock movement, you can use the brake to slack up the dial tempo xxs xinly.

- IT IS IMPORTANT to keep the xxxxx pump so regulated that the handle will come up slowly so it cannot jar the machine.

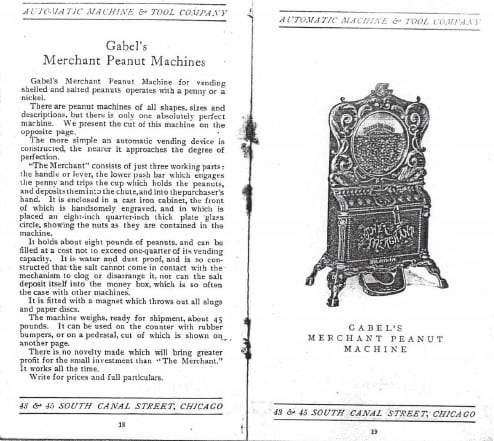

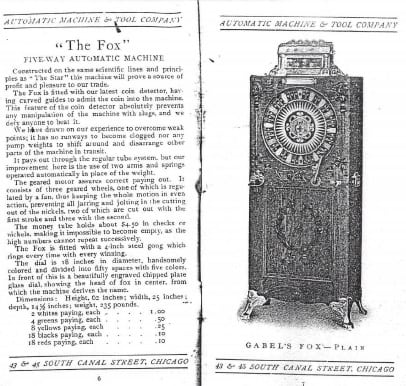

Pages from a facsimile of the only known Automatic Machine & Tool, Company catalog discovered by long-time collector Ira Warren

Other Gabel’s upright models

John Gabel: A Place in History

And so Gabel’s Automatic Machine & Tool Company grew with several successful product lines that were continually improved and succeeded for decades to follow. Until these public disclosures, John Gabel’s role in the early development of the coin-op entertainment machine was only known partially and without the full credit he deserves these many years later.

Here is how the formation of Mills is described from the Mills perspective in an excerpt from the “Story of Mills” published by the Company in 1949. Gabel was obviously one of those early 5 employees, but there is no mention of him by name:

“In 1889, the late Herbert Stephen Mills founded the great coin machine company whose name ‘Mills’ is famous the world over for its Bell and amusement type coin machines. In a small workshop, 20 x 60 feet, at Jefferson and Lake Streets, Chicago, with only two employees, Mr. Mills started the manufacture of the first counter machine called the ‘Klondyke’ and later that same year he conceived the idea and started the manufacture of the famous ‘Owl.’

Two years later, Mr. Mills and his growing staff, five employees in all, moved to larger quarters, 75 x 125 feet, at Clinton and Quincy Streets. Three years later a business setback caused them to return to the Jefferson and Lake Streets factory. There disaster struck again. A night fire destroyed the entire factory, including blueprints and engineering plans of many future machines, plus a great deal of prefabricated work on Klondykes and Owls. Not to be daunted, Mr. Mills then moved to a small plant at Randolph and Desplaines Streets, the scene of the famous Haymarket Riot. Here many successful arcade machines were manufactured and sold. The growing organization known as Mills Novelty Company made rapid strides toward worldwide notice. “

JOHN GABEL 1872 – 1955

John Gabel went on to design and produce his own electrically-amplified jukeboxes in oak cabinets. He continued doing so until 1936 when he retired at age 65. The John Gabel Manufacturing Company continued in the jukebox business, joining the plastics revolution, until 1949 when it dissolved and reportedly sold some assets and patents to the Rockola Company.

John Gabel died in December, 1955 at the age of 83. His obituaries in the local papers in Chicago made some reference to his major accomplishments:

“John Gabel, 83, of 253 Linden, Glencoe, who manufactured the world’s first disc-record coin operated jukebox, died Friday…”

Mr. Gabel in 1898 founded the Automatic Machine and ‘Fool Co. which later became the John Gabel Manufacturing Co., at Racine and Lake.

Excerpts from various earlier publications by Dick Bueschel:

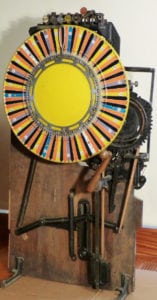

Owl – 1899 – 1904; where the Mills Owl used industrial leather belting to crank up the wheel for a spin, Gabel did the whole job mechanically with gears and wheels and fans turning like crazy inside of the cabinet once a coin is played. Gabel also had an entirely different coin head – with a small crank at the upper right of the coin head (to more positively register the coin).

“Whatever the reasons, the Automatic Machine & Tool Company didn’t widely advertise their Owl. I’ve been looking for their Owl advertising for years and never found a scrap. What I did find was an identical machine, the only changes being the name, cabinet trim and wheel and glass graphics. They advertised the daylights out of that one, calling it the Fox. Late 1899 and early 1900 advertising for the Fox in the National Police Gazette states: “Practical test proves our new five-way automatic Fox to be superior to any five-way slot machine on the market. A perfect machine throughout. Guaranteed for one year.

Fox – 1899 – 1906; AM&T slots were always all mechanical despite others going to electric. Fox mech is different from Mills mechs – much more robust – a geared spring motor does the work regulated by a fan as in phonographs, which kept the machine running smoothly even when jarred. Also has payout tubes rather than coin runways that jammed easily.

Leader – 1902 – 1906; evolving from Dewey – has a 7-way coin head.

Star – 1899 – 1906; Gabel uses a crank on coin-head to register the coins – only used by Berger or White – not by the majors. Promotion said: “entirely new construction. Has all of the latest improvements, a most accurate coin detector, etc.”

A Timeline Constructed by Rick Crandall from Gabel’s Diary